成功案例

四重奏优化中的振荡器动态相位噪声,工程师应

作者: bet356体育官方网站 点击次数: 发布时间: 2025-06-08 09:48

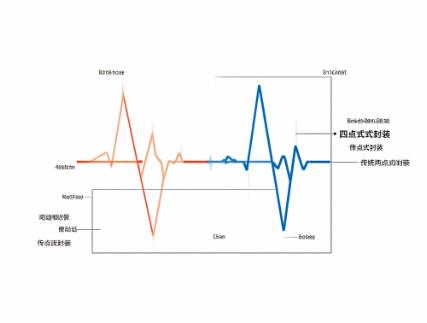

在高速通信和控制系统中,机械振动引起的相位噪声成为主要的性能瓶颈。当石英晶体受外力的影响时,压电的内部效应产生的寄生电压将直接降低时钟信号。实验表明,1G的加速度可能会使典型振荡器的相位噪声恶化为20 dbc/hz(数据资源:IEEETr。Tr。Ultrason。Froelectr。Freq。Control。68)。本文将揭示一系列工业验证的四步优化政策。本文指出:●切割竞争的过程:SC切割晶体显示绝对好处 - γ矢量(加速度敏感性)为0.1 ppb/g,在切割(BLIL实验室测试报告)的1 ppb/g(BLIL实验室测试报告)●包装结构的进化范围更大的频率频率:Vibration的频率较大的频率范围的频率为60%,这是10倍。h as shown in Figure 1 Comparative Data) Two-point Packaging Vibration Curve Curve (Source: Bliley Technical White Paper) Uses dual-modal excitation detection Methods: 1. Sine Sweep: Apply 0.5g acceleration in the range of 10-2000Hz to measure ± 5% after screening, ensuring the consistency of the batch (production line of actually measured data) Hearing Balance Formula Triple Breakthrough: 1. Broadband Coverage: Effective Compensation Bandwidth up to 500Hz (Traditional Solution ≤100Hz) 2. Dynamic noise reduction: Real -time discovery of mgA acceleration signal, and the inverted voltage is formed by DAC to cancel the piezoelectric noise 3. Index Jump: Press the phase noise caused by vibrating to -170 dbc/hz@1khze offset (that -PTIMIZE by 30DB compared to the main solution) Phase to a稳定级别(来源:Bliley应用程序注释AN027)●5G基站应用程序:设备制造商采用了四步优化解决方案后,错误率从10⁻⁶●MIS下降sile Guid System: SC Cutting + Electronic Compensation increases the dynamic stability of the frequency of up to 0.1ppm/g ( successive criteria GJB2242-2017) ● Cost effectiveness ratio: For each USD 1 invested in the mass labor stage, eventually can be wipedn The cost by 8 USD (in Life Cycle Assessment Report) Core Data Traceability: ● Comparison of Crystal Cutting Performance: Quoted from "IEEE UFFC”第68卷第3页●振动测试标准:MIL-STD-810G方法514.8●●振动测试标准标准:补偿系统的MIL-STD-810:Bliley Pterent US 11,578,632 B2当电子补偿技术在电子敏感的情况下,在PPB/G的敏感性时,Electial of Ppb/g ppb/gement collost collost collost of ppb/gement of ppb/gelest of ppb/gelest of ppb/gelest of ppb/gement的敏感性。控制协作。科学整合材料的四步政策(SC切割),机械工程(四点安装)和信号处理(自适应补偿)驱动通信场,AerospaCE,军事行业和其他领域以打破世界颤抖的身体环境,您仍然可以听到准确的时间流逝。

在高速通信和控制系统中,机械振动引起的相位噪声成为主要的性能瓶颈。当石英晶体受外力的影响时,压电的内部效应产生的寄生电压将直接降低时钟信号。实验表明,1G的加速度可能会使典型振荡器的相位噪声恶化为20 dbc/hz(数据资源:IEEETr。Tr。Ultrason。Froelectr。Freq。Control。68)。本文将揭示一系列工业验证的四步优化政策。本文指出:●切割竞争的过程:SC切割晶体显示绝对好处 - γ矢量(加速度敏感性)为0.1 ppb/g,在切割(BLIL实验室测试报告)的1 ppb/g(BLIL实验室测试报告)●包装结构的进化范围更大的频率频率:Vibration的频率较大的频率范围的频率为60%,这是10倍。h as shown in Figure 1 Comparative Data) Two-point Packaging Vibration Curve Curve (Source: Bliley Technical White Paper) Uses dual-modal excitation detection Methods: 1. Sine Sweep: Apply 0.5g acceleration in the range of 10-2000Hz to measure ± 5% after screening, ensuring the consistency of the batch (production line of actually measured data) Hearing Balance Formula Triple Breakthrough: 1. Broadband Coverage: Effective Compensation Bandwidth up to 500Hz (Traditional Solution ≤100Hz) 2. Dynamic noise reduction: Real -time discovery of mgA acceleration signal, and the inverted voltage is formed by DAC to cancel the piezoelectric noise 3. Index Jump: Press the phase noise caused by vibrating to -170 dbc/hz@1khze offset (that -PTIMIZE by 30DB compared to the main solution) Phase to a稳定级别(来源:Bliley应用程序注释AN027)●5G基站应用程序:设备制造商采用了四步优化解决方案后,错误率从10⁻⁶●MIS下降sile Guid System: SC Cutting + Electronic Compensation increases the dynamic stability of the frequency of up to 0.1ppm/g ( successive criteria GJB2242-2017) ● Cost effectiveness ratio: For each USD 1 invested in the mass labor stage, eventually can be wipedn The cost by 8 USD (in Life Cycle Assessment Report) Core Data Traceability: ● Comparison of Crystal Cutting Performance: Quoted from "IEEE UFFC”第68卷第3页●振动测试标准:MIL-STD-810G方法514.8●●振动测试标准标准:补偿系统的MIL-STD-810:Bliley Pterent US 11,578,632 B2当电子补偿技术在电子敏感的情况下,在PPB/G的敏感性时,Electial of Ppb/g ppb/gement collost collost collost of ppb/gement of ppb/gelest of ppb/gelest of ppb/gelest of ppb/gement的敏感性。控制协作。科学整合材料的四步政策(SC切割),机械工程(四点安装)和信号处理(自适应补偿)驱动通信场,AerospaCE,军事行业和其他领域以打破世界颤抖的身体环境,您仍然可以听到准确的时间流逝。 成功案例

新闻中心

ued在线注册

QQ:88889999

电话:020-66889888

传真:020-66889777

邮箱:admin@admin.com

地址: 广东省广州市番禺经济开发区58号